Difference between FRP and GRP

Fibre Reinforced Plastic/Polymer (FRP) and Glass Reinforced Plastic (GRP) are two types of materials that are essential in modern engineering. These two types of materials are used by engineers who make sure that their design and structure of the product remain solid. With the advancement of technology, people demand new types of structures and designs. To meet the demands of their clients, engineers along with chemical specialists have produced different materials that are called composites. FRP is made of fibres and polymer mixture while GRP is made of with glass fibres and reinforced polymer. Basically the difference between the two is based on their composition, usage and resistance to heat.

Instructions

-

1

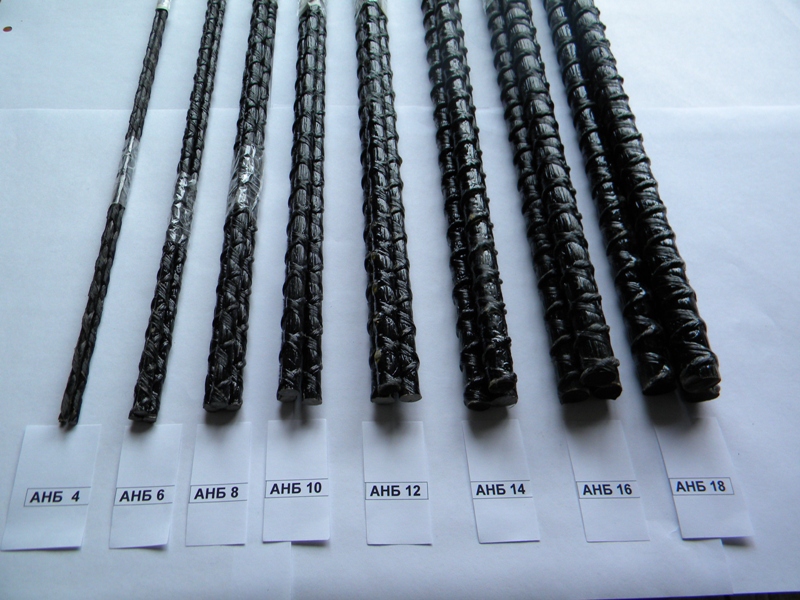

Fibre Reinforced Plastic/Polymer

Fibre Reinforced Plastic/Polymer is made of two types of fibre and a polymer. Chemical engineers always put the right amount of fibre and polymer to strengthen the material. After the mixture of fibre and plastic/polymer, the new material is called a composite. Experts say this material is highly reliable in building large structures and this material is also very durable. Different industries such as civil, biomedical, mechanical, marine and aerospace use composite materials extensively. In this particular mixture, the fibre plays a vital role as it gives strength and stiffness to the entire material. Fibre alone cannot be very productive for building big structures and mixture of polymer provides more strength to the composite material. Different fibres used in these types of materials that include, Aramid, Carbon, Quartz, Spectra 1000, E-glass, S-glass, Carbon, Graphite (P-100) and Boron. Other fibres that are used include, Vinyl Ester, Polyester, Epoxy, Bismaleimide, Polyimide and Phenolic.

- Image Courtesy: weiku.com

-

2

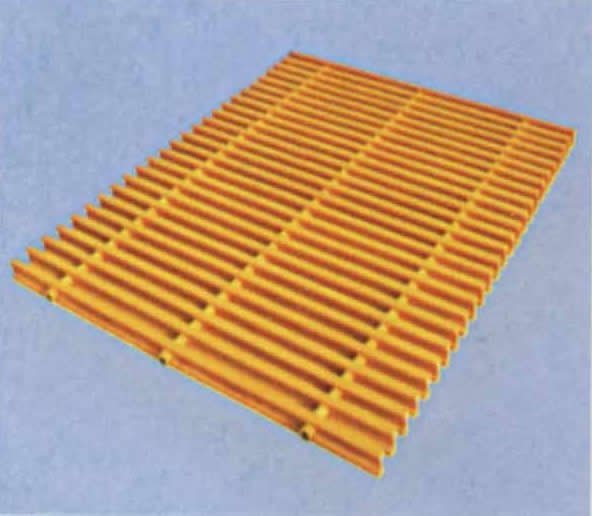

Glass Reinforced Plastic

This material is made out of two components including fibre glass and reinforced plastic. Glass Reinforced plastic is being used in gliders and different kinds of aircraft. This composite material is also used to make boats and their different parts, automobiles, bathtubs, external door skins, hot tubs, roofing products, surfboards, pipes, cladding, cast and water tanks. This material is also considered very strong and can hold various types of other manufactured goods. Over the past few years there has been an increase in the use of Glass Reinforced Plastic as it is the ideal material for maintaining structural strength and long lasting durability.

- Image Courtesy: plasticoncomposites.com